Electric stopper: economical and environmentally friendly

Electric stoppers are characterized by their efficient drive, which can be electromagnetic or electromotive, for example. The fact that electric stoppers do not require compressed air offers numerous advantages: In addition to the positive aspects of less noise and more environmental protection, there is also the higher economic efficiency. All in all, it is also a very convenient solution thanks to the reduced maintenance effort.

Electrically driven stoppers are highly efficient and cost-effective to operate. They are also easier to control and configure than pneumatic cylinders, for example. If all parts of an assembly line can be electrically driven, an air pressure infrastructure can be dispensed with entirely.

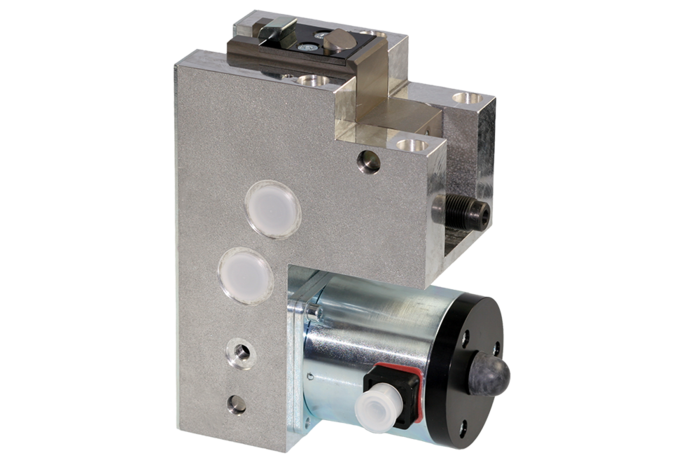

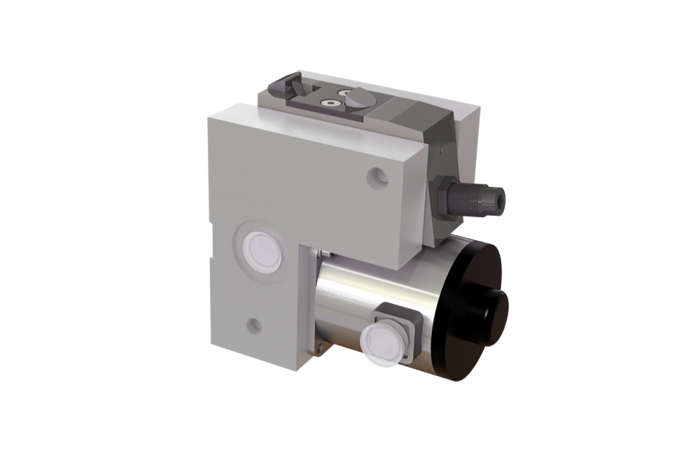

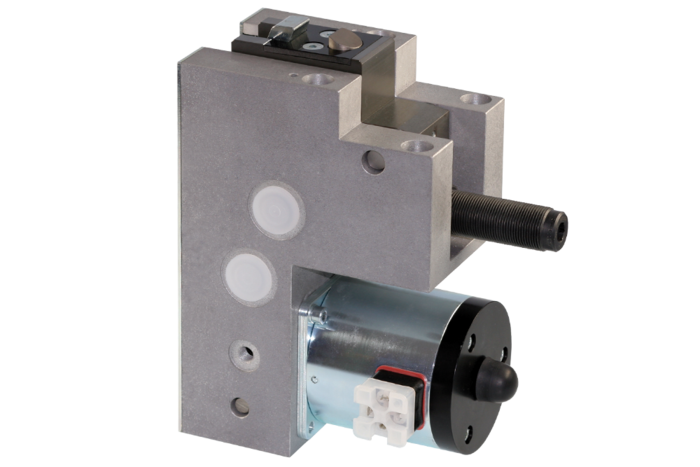

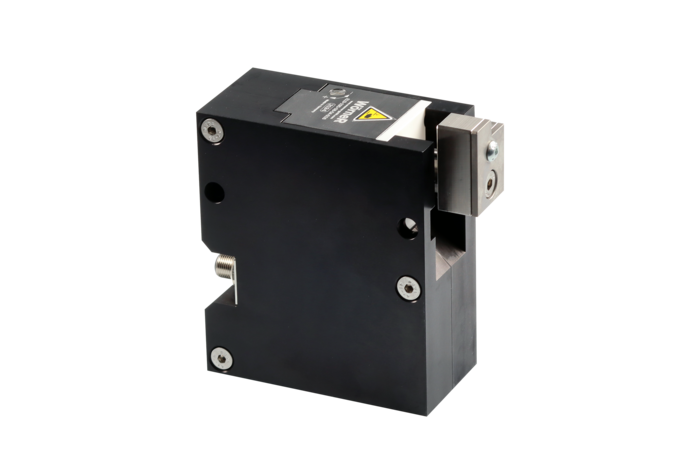

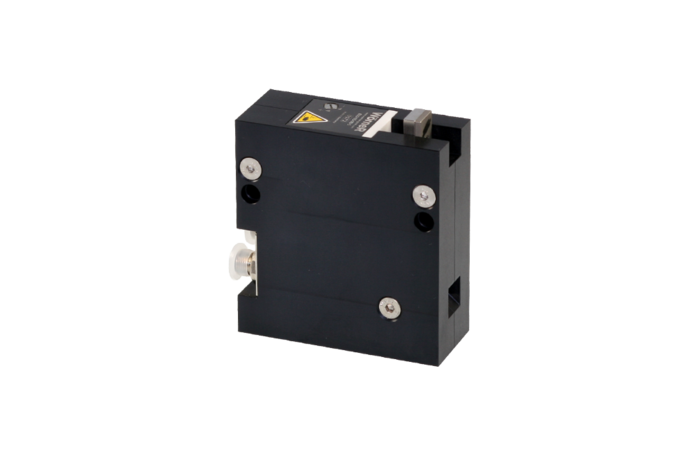

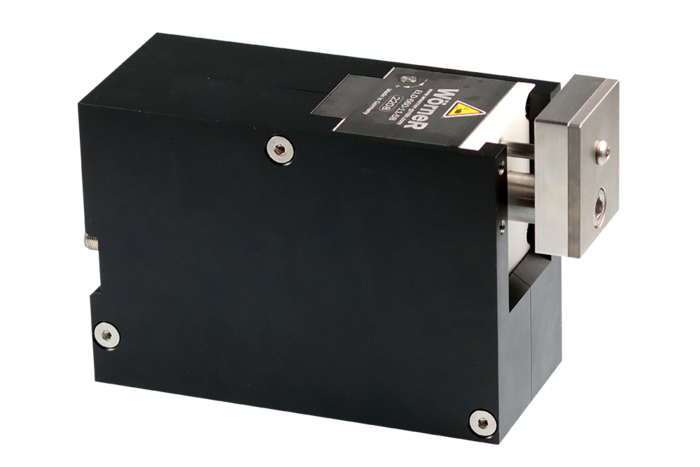

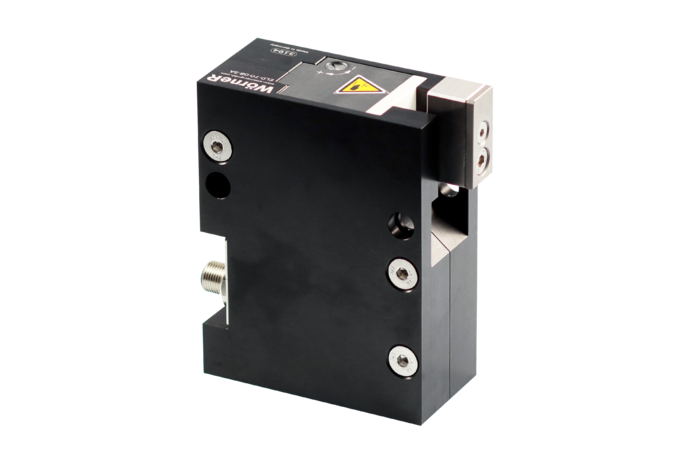

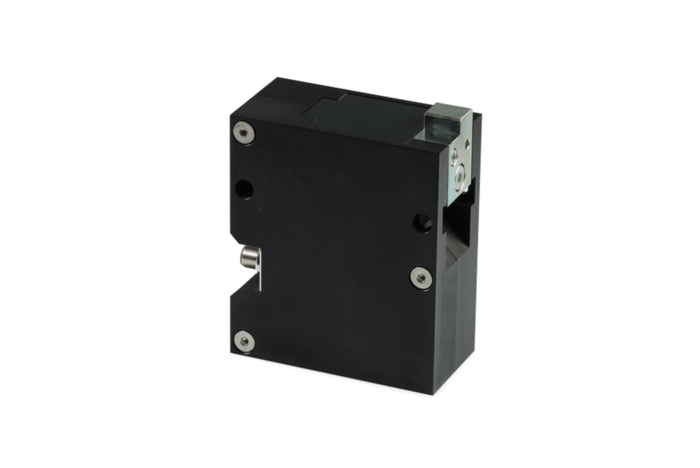

Electric stoppers and separators from Wörner are energy-efficient, easy-to-install and particularly quiet solutions for stopping, separating, positioning and holding workpiece carriers in an assembly line.

Which stopper is right for a particular application depends on the nature of the workpiece and the conveyor system (weight, conveying speed, coefficient of friction, damping required or not). With the Wörner product filter, you can easily and quickly find the right basic product.

With the basic products of the Wörner product range in the areas of electric and pneumatic stoppers, almost all applications can be covered; for special needs, we develop special solutions.

Product advantages of the electric stoppers

Wörner electric stoppers are developed to meet the requirements of a wide variety of industries and have proven themselves successfully in countless production lines. Conveying speed, pallet weight and robustness against external influences determine the selection of suitable Wörner components.

Electrically driven stoppers score with a multitude of advantages:

Electrical stoppers increase overall energy efficiency to approx. 80% - compared to just 6% of pneumatic systems.

Electrical stoppers reduce operating costs by a factor of seven compared to pneumatically powered stoppers.

Since a pneumatic installation is no longer necessary, the installation and set-up procedures are much quicker and simpler.

Numerous models having various sensors, permit additional functions (e.g. temperature monitoring, cycle counter); and various accessories for virtually any application.

All models are very easy to control. Suitable for a variety of PLC types and I/O modules.

Very robust design – tested, proven and successfully applied. Many models are also insensitive to dirt and oil.

Very low noise output, hence particularly suitable for environments where noise must be kept to a minimum.

Therefore, no additional power supply necessary, power supplied via I/O module.